Modernize Without Replacing Your Assets with retrofit solutions for industries in india

Across India, thousands of factories and plants are still running on equipment that is productive but no longer “smart.” These machines were built for durability, not for the data-driven world of today’s operations. In an era of high energy costs, tight margins, and global competition, staying efficient and responsive is no longer optional.

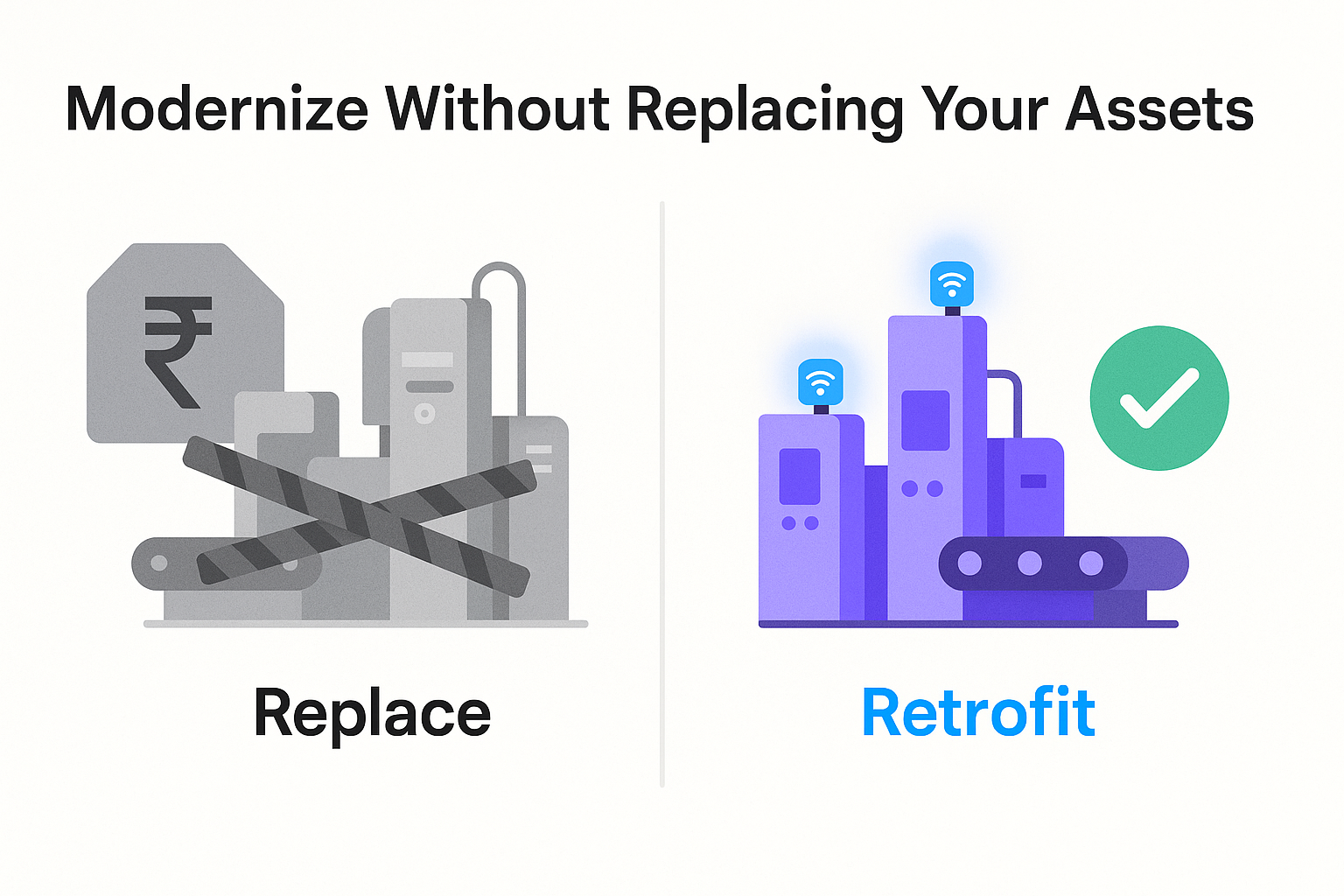

For many operations managers, modernization still means ripping out old equipment and installing new machines. But absorbing huge capital costs, waiting through long lead times, and halting production for weeks is simply not realistic.

This is where retrofit solutions for industries in India change the story. By upgrading existing assets with compact IoT modules, sensors, and software layers, legacy equipment gains the intelligence it needs for predictive maintenance, energy monitoring, and real-time analytics, without disruption.

What Are Retrofit Solutions?

Retrofit solutions for industries in India are technology upgrades that add new capabilities to existing machines. Instead of replacing expensive equipment, you “retrofit” it with smart devices that bring modern features.

This approach – sometimes called retrofit technology, turns legacy assets into connected, data-driven machines. It is cost-effective, fast to deploy, and far less risky than a complete replacement.

Why Industrial Retrofit Solutions Matter

Upgrading with retrofit technologies gives manufacturers and utilities a clear path to improvement without the pain of starting from scratch:

Lower capital expenditure – Installing sensors and controllers costs a fraction of buying new machines.

Minimal downtime – Retrofit tech can often be installed in hours or days instead of weeks.

Faster ROI – Efficiency gains, reduced energy waste, and fewer unplanned stoppages translate into savings from day one.

Sustainability – Extending the life of existing assets reduces scrap and the environmental impact of new production.

These advantages explain why more businesses are embracing industrial retrofit solutions in India.

Key Retrofit Tech Use Cases

Predictive Monitoring to Prevent Failures

Adding vibration, temperature, or pressure sensors to legacy machines lets you detect anomalies before breakdowns occur. This reduces unplanned downtime and extends equipment life.

Energy Insights to Cut Waste and Improve Margins

Retrofit energy meters and smart MCBs track consumption at a granular level. Operations teams can identify inefficiencies and reduce costs without sacrificing output.

Cloud Visibility for Smarter, Faster Decisions

Retrofit IoT gateways push real-time data from the shop floor to the cloud. Managers and engineers can monitor performance from anywhere, enabling quicker responses and better planning.

These examples show how retrofit tech converts “dumb” equipment into connected, data-driven assets.

Retrofit vs Replace: The Real Cost of Modernization

| Factor | Replace Assets | Retrofit Existing Assets |

|---|---|---|

| Capital Cost | High | Low |

| Lead Time | Months | Days or Weeks |

| Downtime | Weeks of production lost | Minimal disruption |

| Return on Investment (ROI) | Slow, often years | Fast, measurable within months |

| Sustainability | Scrapping old machines | Extending life of current assets |

For most factories, retrofit solutions offer the practical path forward, especially in India where many industries still rely on heavy, long-lasting machinery.

Why Retrofit Solutions for Industries in India Are Growing

Several factors are driving adoption of retrofit solutions for industries in India:

Rising energy costs and pressure to improve margins.

Need for predictive maintenance and reduced downtime.

Government and corporate sustainability goals.

Increasing availability of affordable retrofit technologies such as sensors, smart controllers, and analytics software.

Indian manufacturers can leapfrog to smarter operations without massive capital investment.

How SmarDen Delivers Retrofit Solutions

SmarDen specializes in retrofit solutions for industries in India. Our approach integrates custom IoT hardware and software with your existing systems, turning legacy assets into connected, intelligent machines.

We offer:

End-to-end retrofit tech design – from sensors to dashboards.

Seamless integration with PLCs and legacy controls.

Custom analytics and cloud visibility tailored to your operations.

Predictive and preventive monitoring modules that reduce downtime.

Energy monitoring solutions to cut waste and improve margins.

Because our solutions are retrofit-friendly, you don’t have to invest in new machinery or endure long shutdowns. We help you extract more value from what you already own.

Practical Examples of Retrofit Technology

HVAC & Energy Monitoring for NPCL

SmarDen deployed its retrofit IoT energy monitoring modules across multiple NPCL facilities. Without replacing any existing chillers or pumps, our system now tracks energy usage in real time, sending alerts for anomalies and helping the client cut energy waste by up to 15%.

STP Automation for ZWC

At a large sewage treatment plant run by ZWC, SmarDen installed retrofit sensors and controllers on existing motors and pumps. The plant now runs on automated schedules with cloud visibility and predictive maintenance alerts, all without shutting down operations or investing in new machinery.

Cold Chain Monitoring for SubZero

For a leading cold chain provider, SmarDen added smart energy meters and temperature sensors to their existing refrigeration units. Managers now see power and temperature trends across sites and can act before losses occur, saving thousands each month.

Lighting Automation for BlueStone Jewellery Stores

SmarDen retrofitted store lighting systems with wireless control modules, enabling remote scheduling, energy savings, and consistent ambience across locations without any rewiring.

Extract More Value from What You Already Own

Upgrading doesn’t have to mean starting from scratch. Retrofit technology lets you keep your existing assets and layer on the intelligence you need for predictive monitoring, energy insights, and cloud-based decision-making.

This approach turns “legacy” into “smart” without disruption, giving you immediate operational gains and a stronger competitive edge.

Where does your operation stand today – replace or retrofit?

If you’re ready to explore retrofit solutions for industries in India, contact SmarDen for a free consultation and see how your legacy assets can become your next competitive advantage.

Contact us for free consultation or Follow us on Instagram